General:

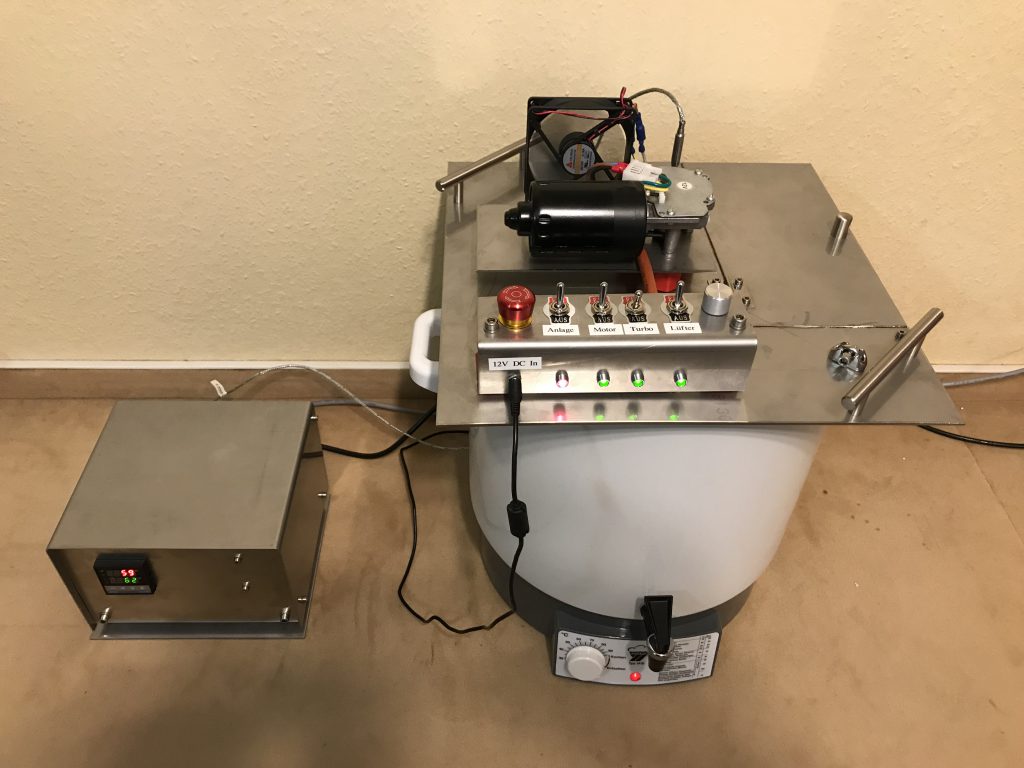

The “Rührteufel 2.0” is based on the “Rührteufel 1.0“. It extends this with the external temperature control “Malzflüsterer” which is perfectly matched to the “Rührteufel 1.0”. Of course, the malt whisperer also placed great emphasis on quality, flexibility and safety.

Quality:

The housing of the “Malzflüsterer” is made of V2A stainless steel, the front plate is made of aluminum for better heat dissipation of the SSR screwed to the front plate. It is large enough to easily accommodate future extensions for the “Rührteufel 3.0”. A potential-free NiCr-Ni type K jacket thermocouple according to DIN IEC 584 with a temperature resistance up to 1200 ° C and protection class IP65 is used as the temperature sensor. The cable from the sensor to the PID controller (REX C100) is designed as a high-temperature resistant glass fiber cable. The immersion depth of the sensor can be adjusted using a V2A compression fitting with a PTFE ring. The setpoint temperature is set on the controller and the actual temperature is also displayed. A contactless SSR (Solid State Relay) with high switching capacity is used for switching.

FUNCTIONALITY:

In order to be able to adapt to the height adjustability of the impeller (brewing paddle) on the one hand and to be able to react to different filling quantities of the mashing pan on the other hand, the immersion depth of the sensor can be adjusted using a V2A compression fitting with a PTFE ring. The mash setpoint temperature is preselected manually on the controller and, when reached, is kept within very narrow limits by the control unit.

Safety:

The “Malzflüsterer” is connected to the “Rührteufel” via an IP54 protected socket, the sensor has protection class IP65. The cable from the sensor to the malt whisperer is a highly heat-resistant glass fiber cable.